Energy saving

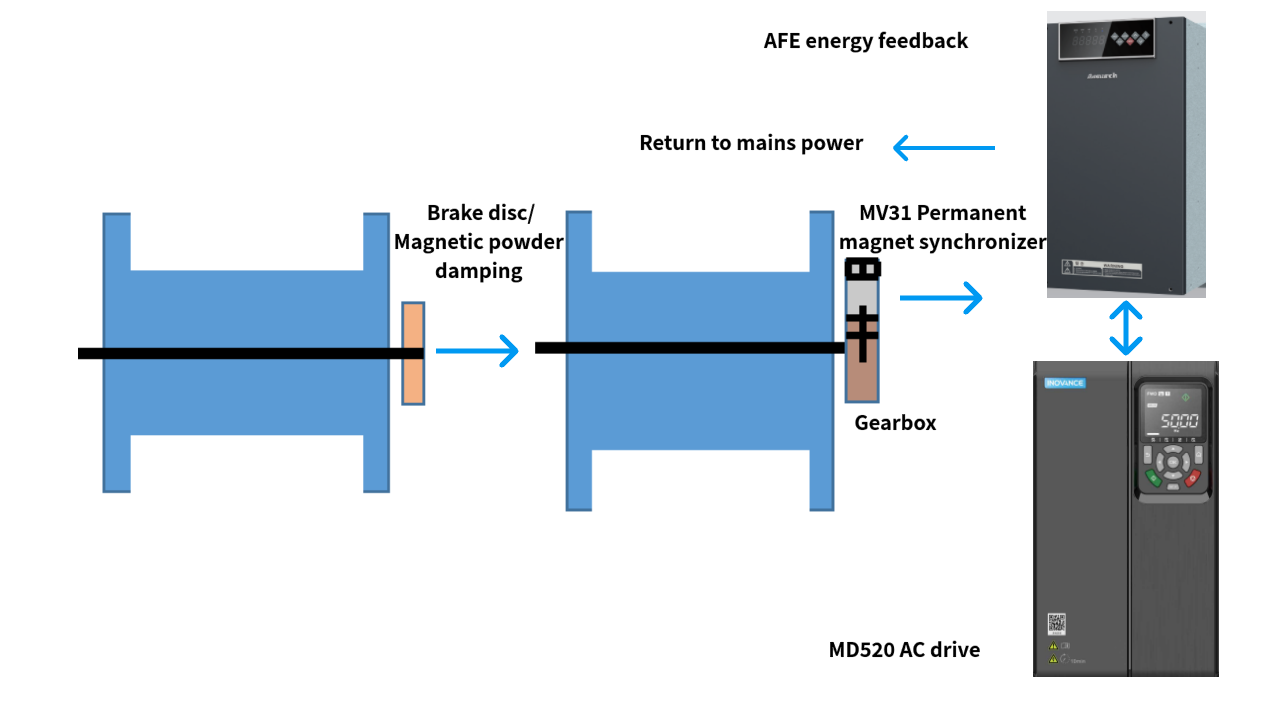

When the cable is pulled, the motor generates power and the AC drive feeds back to the grid through the energy feedback unit. No waste of resources, energy saving and environmental protection.

Long-term cost reduction

No supplies are required after the retrofit, which saves material and labor costs.

Optimized noise reduction, improving the working environment

Resolved the problem of loud noise during brake disc running.

Flexible control of forward and reverse jog, improving operating efficiency

Forward and reverse jog for easy operation.

Log out reminder

Log out reminder